Applied research success stories

As a result of the successful applied research, the scientific teams of ICPF applied for and got granted more than 20 patents. More patents and prototypes are being prepared within the applied research projects with our commercial partners. For the illustration of our cooperation, we present a few selected success stories.

Preparation of Helicenes

Within the Ministry of Industry and Trade project, the Group of advanced materials and organic synthesis – GAMOS cooperated with the commercial company Lach-Ner s.r.o. on the production technology for different helicenes in multigram amounts. The developed technology was directly implemented into the production lines and the helicenes are currently distributed by Lach-Ner not only to the Czech Republic but also to the rest of the world (http://www.lach-ner.com/heliceny/t-396/).

Luminophore recycling

During the research of the advanced recycling technologies, our team developed a novel process for the chemical disposal of the waste luminophores from the electronic devices. Apart from the dispoal of the toxic components, the process yields the valuable by-products – the yttrium and europium oxides. In cooperation with the Safina Vestec, a.s. company, we designed and constructed the production line for the recycling of the waste containing the lanthanoids. As the next stage, the team focuses on the recycling of the permanent magnets or the metalhydride batteries. The novel recycling technology was awarded the Prize of Health and Safe Environment 2006 by the Business Leaders Forum.

Decrease of CO2 emissions from biogas stations

A project with ČEZ was focused on the upgrade of a biogas station regarding its effects on the Global warming potential. Namely, we focused on diminishing of the greenhouse gasses content produced by the co-generation unit of the biogas station. The solution was based on the pilot testing of the possible CO2 capture by the Chlorella microalgae cultivated in the model photo bio reactor. After the cultivation and partial CO2 capture, the algae were recycled back into the fermenters as a substrate. The obtained results can be used in the practical feasibility study of this technology in the full industrial scale.

Electrodiffusion diagnostics

Electrodiffusion (ED) method employs the electrochemical technique of limiting diffusion currents to hydrodynamic measurements of wall shear rates and bulk velocities in flowing liquids. The ICPF team designed and constructed a unique instrument including the ED probes and the control and evaluation software. The ED interface is an automated potentiostat for the multichannel measurement that can be used in the conventional experimental setups as well as in the microreactors. Currently, these instruments are used for the advanced hydrodynamic research at the universities in Lyon, Nantes and La Rochelle.

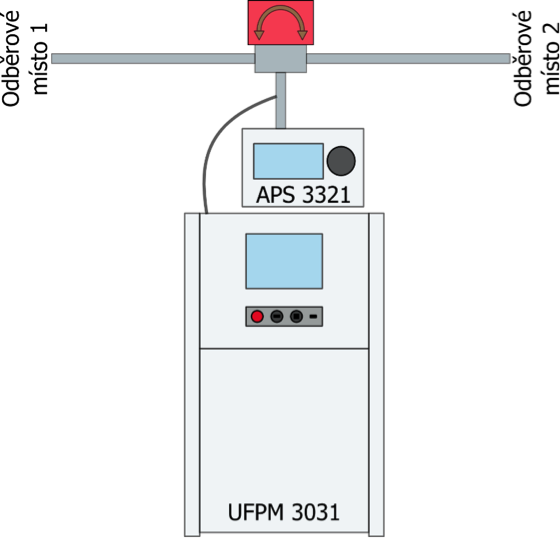

Basamatikum

Another unique instrument designed and assemble at ICPF is the combined wide size range aerosol spectrometer Basamatikum 1.0TMallows to measure particle number size distribution in a range between 20 nm – 20 µm. The instrument separates the measured aerosol particles into 58 size bins. The instrument can automatically switch the scanning between two sampling points (e.g. indoors and outdoors). It consists basically from two aerosol spectrometers (UFPM and APS), electrically actuated ball valve, sampling tubing with isokinetic subsampling to both of the two spectrometers and two sampling lines. The overall control, data logging and saving to file, the switching between sampling lines and the user interface is provided by the means of the LACP-made (Laboratory of Aerosol Chemistry and Physics) software in LabVIEW programming environment.

Schematics of Basamatikum spectrometer.

Microwave Technology for Recycling of Waste PET Bottles

New technology has been developed in order to solve problems of accumulation of waste PET bottles. This recycling technology is based on use of microwave energy for PET depolymerization and it is characterized by low energy consumption and by high purity of products (terephthalic acid, monoethylene glycol) so called “polymer grade” quality. It was tested on pilot plant with capacity 1-10 kg/h PET bottles with MW reactor of 0.12-1.0 m3. This new technology is protected by patent documents both in Czech Republic (CZ299908) and in five foreign countries (PCT/EP/2008/058917), namely in Germany, Italy, France, UK and China. The technology was developed by the Czech Center of Microwave Technology at ICPF.